Brushing Glazes Made Easier

Sometimes we have a great glaze that works well when it is dipped, poured or sprayed on but try and brush with it, and that is a whole other issue. Choosing glazes formulated for a brushing application and using glaze additives in glazes that are not already formulated for brushing is the key to making that great glaze behave beautifully when brushed.

Make brushing on glazes the most relaxing part of your ceramic process. We are going to help you turn those glazes that don't spread evenly and dry way too fast into glazes that you will love to brush with.

Here is a story you may be able to relate to, “I bought a glaze from Bailey in the 5 lb dry mix. I mixed it well with water and sieved it through a Talisman Sieve. The dry mix made about a half gallon of glaze and I dipped a few pots into it with good success. It adhered well and dried quickly. When I went to brush it onto a piece the brush stuck to the pot and the glaze wouldn't spread at all. ”

As a general rule, commercial glazes that come in liquid form, especially small sizes like pints and 2-4 ounce containers, are formulated for brushing unless otherwise noted. Choose these glazes if you are brushing. There will already be ingredients added to keep the glaze particles in suspension longer and to help the glaze flow smoothly off the brush. Commercial glazes in the dry form that you mix with water or glazes that you mix yourself from a series of raw materials need to be conditioned with a glaze additive to improve the glaze’s brushing performance.

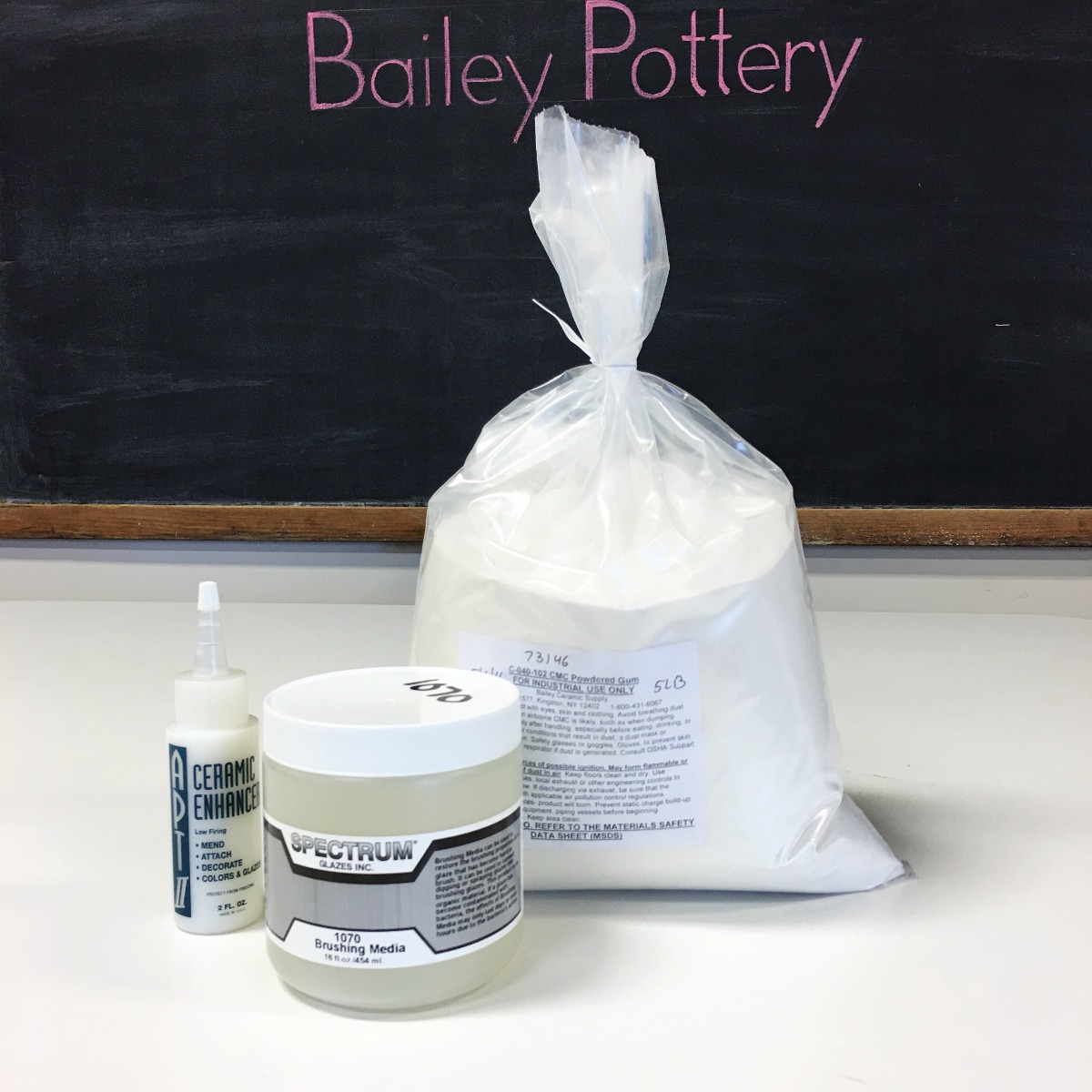

Our favorite glaze additives are CMC Gum, Spectrum Brushing Media, both organic cellulose gums, and Apt II Ceramic Enhancer, an acrylic based medium. Each of these additives has the ability to keep glazes in suspension and extend the drying time for a smooth application. The easiest way to test how much of a glaze additive you need in a particular glaze is to simply introduce one of these additives in liquid form drop by drop into a pint of your liquid glaze until the desired consistency has been reached. Keep in mind that CMC Gum is a powder that needs to be converted into a liquid solution. To do so, mix 1 to 2 tablespoons CMC Gum per gallon of warm water and let stand for 24 hours, and then add to your liquid glaze.

You can also follow these ratios when adding glaze additives to liquid dipping glazes. Use one part of CMC Gum Solution to two parts water when mixing a glaze. Add the Spectrum Brushing Media at 5 percent and up to 10 percent of the volume of the glaze being adjusted. For APT II Ceramic Enhancer, add 3-4 drops per ounce into liquid glazes.

Get yourself a soft, thick brush, and there you have it, brushing glazes made easier.

You can shop for glaze additives here and if you so desire, subscribe to our newsletter for more Tips and Techniques.

Share this post

About the Author

Related Posts

17 Best Selling Green Glazes

How to Make Glazes From a Dry Mix

New Mayco Stoneware Glazes!

AMACO Teacher’s Palette (TP) Glazes

31 of Our Favorite Orange Glazes

Topics

- Customer Service

- Clay

- Bailey Electric Kiln

- Glazes

- Decals

- Throwing on the Wheel

- Ceramic sculpture

- Holiday Project

- Bailey Slab Roller

- Mystery Pot

- The Bailey Collection

- Ceramic Museum

- Kiln Shelves

- Pottery

- Pottery

- Kiln Maintenance

- Ceramic Artist

- Ceramic Tile

- Ceramic Project

- NCECA

- Workshop

- Ceramic Tools

- Atmospheric Firing

- #MadewithaBailey

- Community

- Underglaze

- Gift Guide

- Ceramic Technique

- GR Pottery Forms

- Hydrobat

- Bailey Extruder

Tags