Burner Design & Safety Systems

Bailey 360 Down-Draft Kilns... a Triumph of Logic and Innovative Thinking

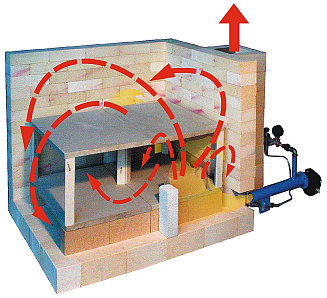

Energy Efficient 360 Convection

Thermocouple Based Flame Safety System

Bailey Gas Kilns are the by-product of logic and innovative thinking. Our unique down-draft design represents years of careful research. Every aspect of fuel efficiency, firing consistency and durability has been incorporated into each kiln. We can say quite confidently that there is no other kiln design that can provide such unparalleled performance.

Uniform Heat Distribution

The Bailey down-draft gives a unique 360 degree heat flow pattern. This flow pattern maximizes the absorption of the heat energy and dramatically reduces firing costs. You get uniform heat top to bottom, front to back, and side to side. Unlike venturi style downdraft kilns with burners coming through the floor, our forced air downdraft kilns offer ingenious internal adjustments to fine tune the path of the heat flow. By adjusting the placement and size of the target brick, we can optimize firing results for traditional pottery forms or sculpture. Just watch those cone packs drop evenly!

Uniform Atmospheres

The 360 degree heat travel also gives excellent control of the atmosphere. Whether you fire oxidation or reduction, atmosphere control is extremely simple. We take the mystery out of firing and make it easy to get perfectly consistent firing results. You can look forward to beautiful glazes in every part of your kiln.

Bailey forced draft burners are mounted up off the floor for convenient easy access. Most venturi burner designs require the operator to crawl on the floor to adjust the burners. Because the Bailey has only two burner ports, there is no heat loss or re-oxidation problems which is typically the case with multiple burner venturi kilns where the burner ports can not be sealed. Venturi kilns are ultra sensitive to the general atmosphere and prone to wide variations in reduction results. Besides the damper, there is no flexible control for internal circulation on a venturi kiln. Heat gets trapped in the top. Debris can fall into the burner ports on the floor and obstruct the flame entry.

___

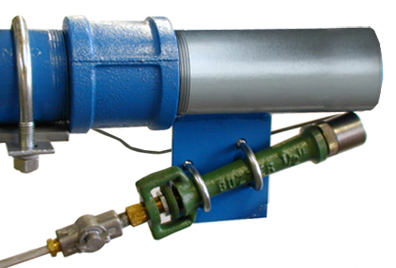

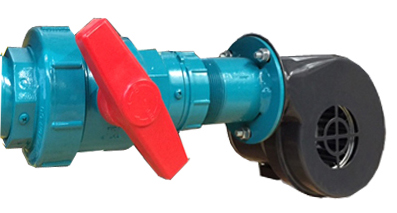

Stainless Steel Burners

Starting in September 2015, Bailey forced air burners are made totally of stainless steel tubing with an internal stainless flame retention nozzle. This prevents rust from accumulating in damp environments and soda firing applications.

Accurate Simplistic Air Controls for Burners

The Studio Standard series, Studio Deluxe series, and the PRO 28, 32, and 40 kilns all have a simple single control valve to supply air simultaneously to both burners. There is no need for balancing the air individually for the left and right burners, it's done automatically.

High Limit Control Systems and Programmable Controllers

Thermocouple Based Flame Safety System

High Limit #1 Shut Off System (optional)

This unit offers added back-up shut-off safety in the event that something prevents the operator from turning the kiln off at the peak temperature. If a gas kiln is allowed to “run away,” it has the potential of building up temperature that could cause damage to the kiln, the load, and a potential fire hazard. The High Limit consists of an adjustable electronic controller (to set a shut-off temperature), which is connected to a gas solenoid. Once the temperature “set point” on the controller is reached, the supply of gas is terminated, and the kiln is switched off. Electrical interruptions will cause the system to shut down the kiln as well. A 120 volt standard outlet is required. This unit is highly recommended for schools, or other situations where a kiln is going to be installed in a building.

M-404-090 High Limit #1 Shut Off

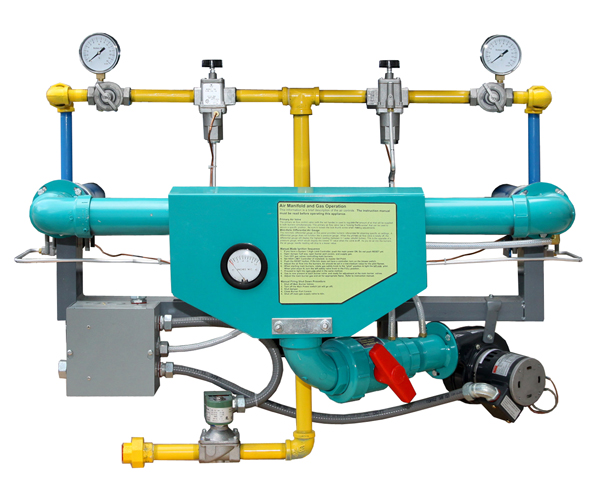

High Limit #3 Safety Flame Systems

(optional for kilns under 300,000 BTUs)

(required for kilns over 400,000 BTUs)

This system includes a High Limit Controller, Soak Control Function, Ultra Violet Safety System, Fire Eye Controls, Thermocouple, Solenoids, and Automatic Ignition System.

The U.V. Scanners will shut down the kiln within several seconds if there is a flame-out. The soak control will hold the kiln at a given temperature for as long as you require. The ignition system will automatically light the burner manifold with the flick of a switch. if the burner goes out, it will relight the burner automatically. If re-ignition is not possible, then the entire system will shut down.

Required for kilns over 40 cu. ft. stackable space, elective on all smaller models.

Recommended for Schools.

M-404-005 Digital UV High Limit System #3

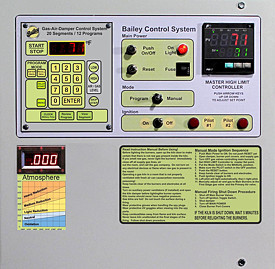

8 Segment Programmable Controller

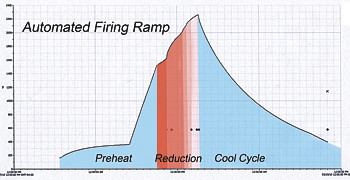

With the addition of our 8 Segment Controller, you can program your gas kiln to fire by ramp rates. This unit will hold 6 programs, (4) are 8 segment capability, and (2) are 16 segment capability. You can enter a "preheat" program for a reduction firing the night before (with a delayed start) which is very convenient to shorten the length of the firing the following day. You start the pilots the night before with the controller programmed for a specific heat rise rate to a designated temperature goal where you intend to begin reduction in the morning. Using the delayed start function, the kiln will begin cycling the heat in the early morning to meet the programmed ramp rate schedule. When you arrive in the AM, you just switch to manual mode and put the kiln into reduction. The controller can also be used to down fire the kiln to achieve crystalline glaze effects. This programmable controller will not adjust the damper and would not be used for an entire firing process.

M-404-005 Digital UV High Limit System #3

8 Segment Programmable Controller with High Limit #1 Back-up Shut-off

This version incorporates both the programmable ramp rate controls with the High Limit #1 back up controller or the System #3 UV high limit system.

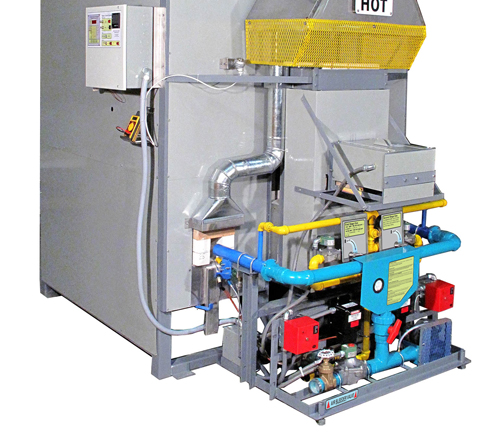

Bailey “Advanced Logic" Programmable Gas Fired Kilns

This new generation of Bailey ENERGY SAVER gas kilns, produces consistently reliable & beautiful reduction or oxidation firings.

It can be manually fired or program fired, and even allows delayed starts so your kiln is at body reduction temperature first thing in the morning! The motorized damper makes all the necessary adjustments for the complete firing, oxidation or reduction.

Beautiful Glazes with Bailey Advanced Logic Reduction!

Bailey “Advanced Logic" Programmable Gas Fired Kilns

This new generation of Bailey ENERGY SAVER gas kilns, produces consistently reliable & beautiful reduction or oxidation firings.

It can be manually fired or program fired, and even allows delayed starts so your kiln is at body reduction temperature first thing in the morning! The motorized damper makes all the necessary adjustments for the complete firing, oxidation or reduction.

Beautiful Glazes with Bailey Advanced Logic Reduction!

Bailey Gas Kilns are 100% Certified for the US.

Bailey Gas Kilns are approved and certified for the US. Add this to the long list of advantages in owning a Bailey Downdraft Gas Kiln. You get great dependable firing results, highly energy-efficient firings, superior technical support, and many innovative design features that are not found on any other kiln.