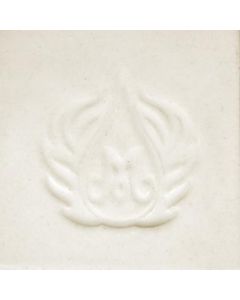

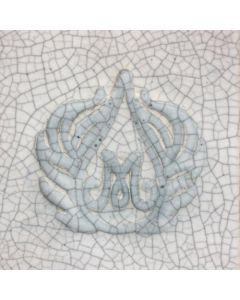

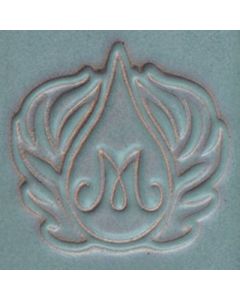

Stoneware

Stoneware glazes offer the depth, sophistication and reliability to artists working from mid-range to high-fire temperatures. Many glazes will break over textures, revealing secondary colors and shades. The choice of clay body, thickness of glaze application, firing process and temperature will affect the fired results.

Used alone, stoneware glazes produce beautiful color variations; one coat will allow the clay body to show through the glaze and two to three coats deepen the color.

Tips for Micros (SW214 - 218)

• Micro is short for micro-crystalline which is a glaze that develops small crystallization from the zinc and silica during the cooling process. These glazes can be fired from cones 5-10, but we suggest a hot cone 6 with a fast cool in a loosely packed kiln for optimum crystallization.

• While Mayco’s Stoneware Crystal glazes contain glass frit in the jar, Micros do not contain a glass crystal, rather, the effect is created by the glaze itself during the firing process.

Tips for Crystals

• Crystal glazes are designed to expand upon the surface with dazzling bursts of color.

• Crystals will settle to the bottom of the jar and will need thorough mixing prior to initial use and in between each coat.

• Apply two to three coats using a fan brush. While the glaze is wet, use your brush to redistribute crystals to achieve balanced coverage. Over-application of the crystals can cause pinholing or running.

• Crystals can create movement. Avoid having a heavy concentration of crystals near the bottom of your piece.