Pyrometric Cones for Kiln Firing

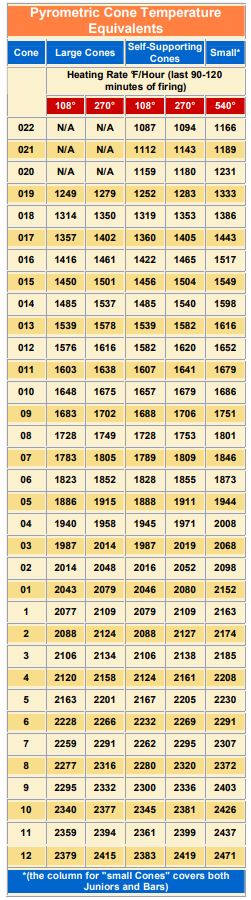

Orton Pyrometric Cones: The chart below lists the temperature equivalents for Orton Cones based on specific heating rates. Cones measure ‘heat work’ which is the combined effect of time and temperature. Clay and glazes are formulated to mature when a certain amount of heat work is achieved. A pyrometer reads temperature only and does not take into account the amount of time it takes to reach that temperature. Firing by the temperature reading alone may not produce enough heat work to properly mature your clay or glaze. When the proper amount of heat work is reached, the cone will bend. In order for a cone to bend at the temperature listed, the heating rate shown at the top of the column must be maintained for the last 90-120 mins of the firing. As you can see, the final temperature will change based on the heating rate: a slower rate will bend a cone at a lower temperature than a faster rate. As long as the cone bends, the proper heat work has been achieved. Witness cones should be used in every firing to verify your heat work. This is particularly important when problem-solving firing defects or computer error messages. Only Large or Self Supporting cones are used as witness cones. Junior or Bar cones are for use in the Kiln Sitter. Only the witness cones tell you if the proper heat work is achieved. Do not depend on the Kiln Sitter to determine the heat work. A series of 3 cones are used as witness cones: the Target Cone (the cone you are firing to), the Guide Cone (one cone below) and the Guard Cone (one cone above). Read on for proper use of Witness Cones. This information is also outlined in a pdf located in the description under all Large and Self Supporting Cones. Also read on for Kiln Sitter usage, which is also outlined in a pdf located in the description under all Junior and Bar Cones. If you have any additional questions, please call us at 800-431-6067.

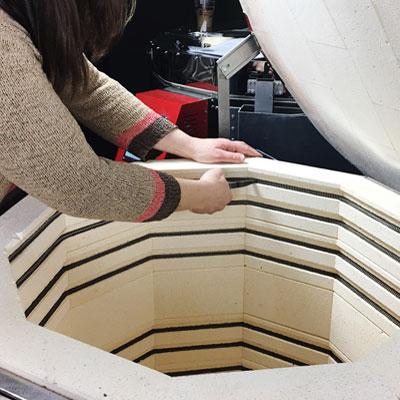

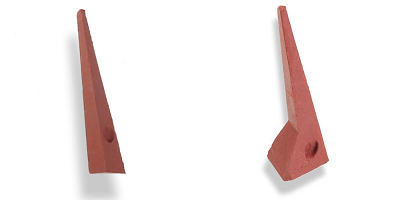

Large Cone, Self Supporting Cone

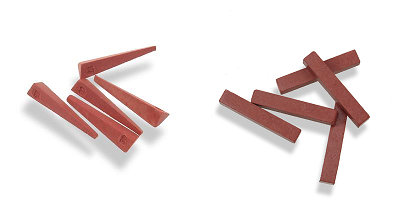

Junior Cones, Bar Cones

Using Witness Cones:

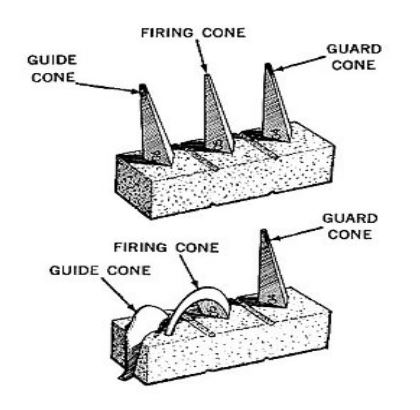

To use witness cones, select 3 cones as follows: A Guide Cone - One cone number below your goal. A Fire Cone - The cone number you wish to achieve. A Guard Cone - One cone higher than your goal.

Place standard large cones in a holder or cone plaque designed to hold them at the proper 8-degreeangle. If using self-support cones, their special built-in base will place them at the correct angle. Place cones in order: Guide\Fire\Guard. (For example, to fire to cone 05, place the cones facing left 06\05\04). This allows each cone to melt without interfering with the others. Cone plaques should be visible through your kiln’s spy holes during firing so that you can monitor your progress and manually shut down if automatic devices should fail. Additional cone plaques can be placed in other areas of the kiln for analysis after firing is completed. They will tell you if your kiln fires evenly throughout or where your hot and cold spots are.

Kiln Sitter:

A Kiln Sitter is a valuable shut-off device, but should not be considered the determining factor with reference to proper heat work. The cone in the sitter has additional variables that affect its melt: proximity to the kiln wall and elements and the weight of the sensing rod resting on it. When a Junior Cone is used, the tapered shape can cause variances if positioned too far right or left. (We recommend Bar Cones to eliminate this variable). Because of these other factors, a kiln sitter cone can deform prematurely, shutting down the firing before proper heat work is complete. Witness cones will tell you if this happens and adjustments to the sitter can be made if necessary. Use only Large or Self Supporting cones as your Witness Cones.

Programmable Controllers are much more accurate than kiln sitters if you pay attention to your ramp rates - especially toward the end of the firing. By following the heating (ramp) rate on Orton’s Cone Chart for at least the last 90-120 minutes of firing, you can be fairly certain that the degree temperature equivalent on the chart will be the end point of your firing. Even so, only visual cones will confirm your heat work and allow you to adjust your firing profile if necessary.

Use witness cones in every firing: Both Kiln Sitters and Controllers can fail due to mechanical malfunction. In either case, properly using witness cones will ensure that you don’t experience a serious meltdown. Cones are cheap; kilns are not.

Shop Cones