#MadewithaBailey Interview with TC Staton

TC Staton

Instagram: @coneinfinity

You've posted some amazing glaze results on Instagram, can you tell us a little bit about what you are up to?

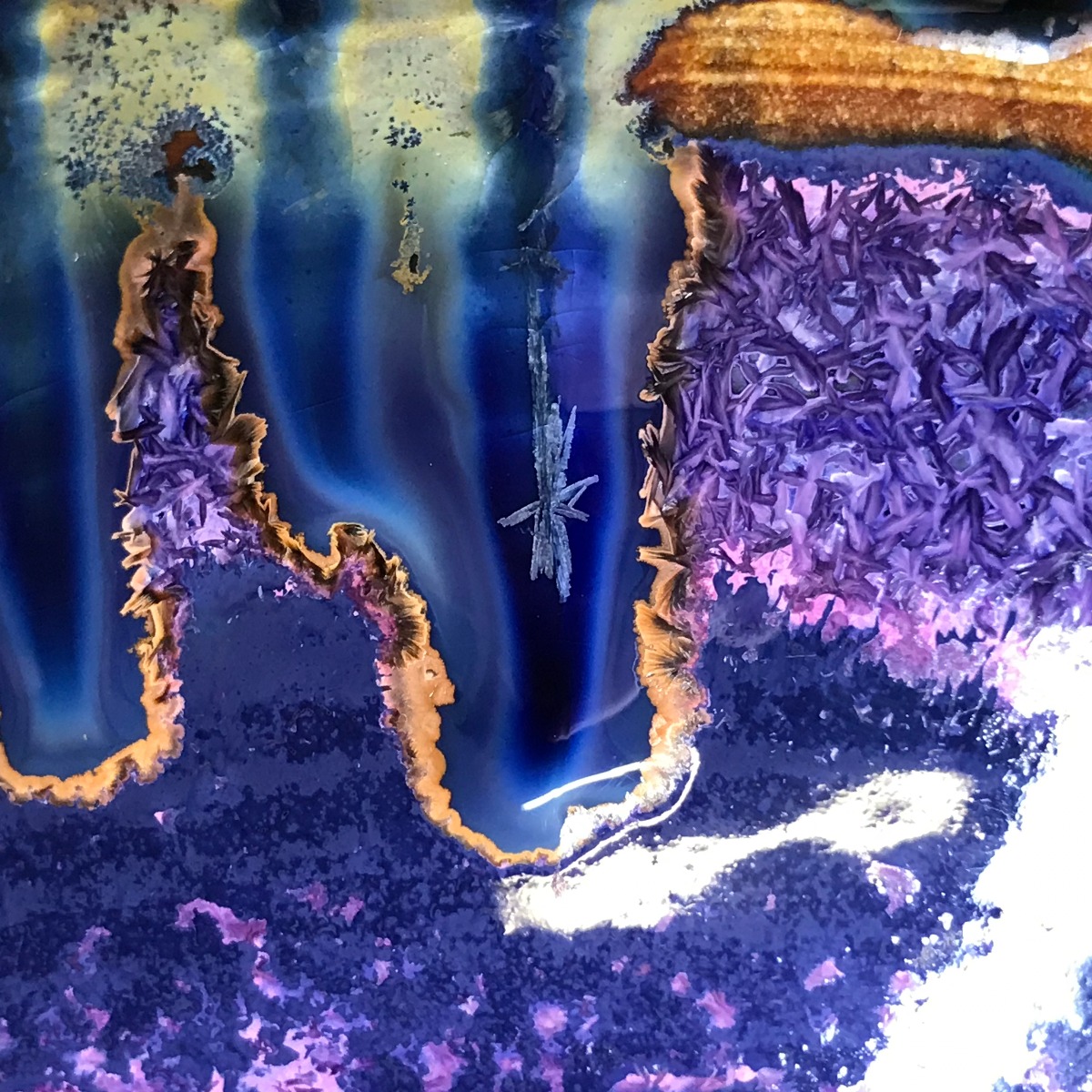

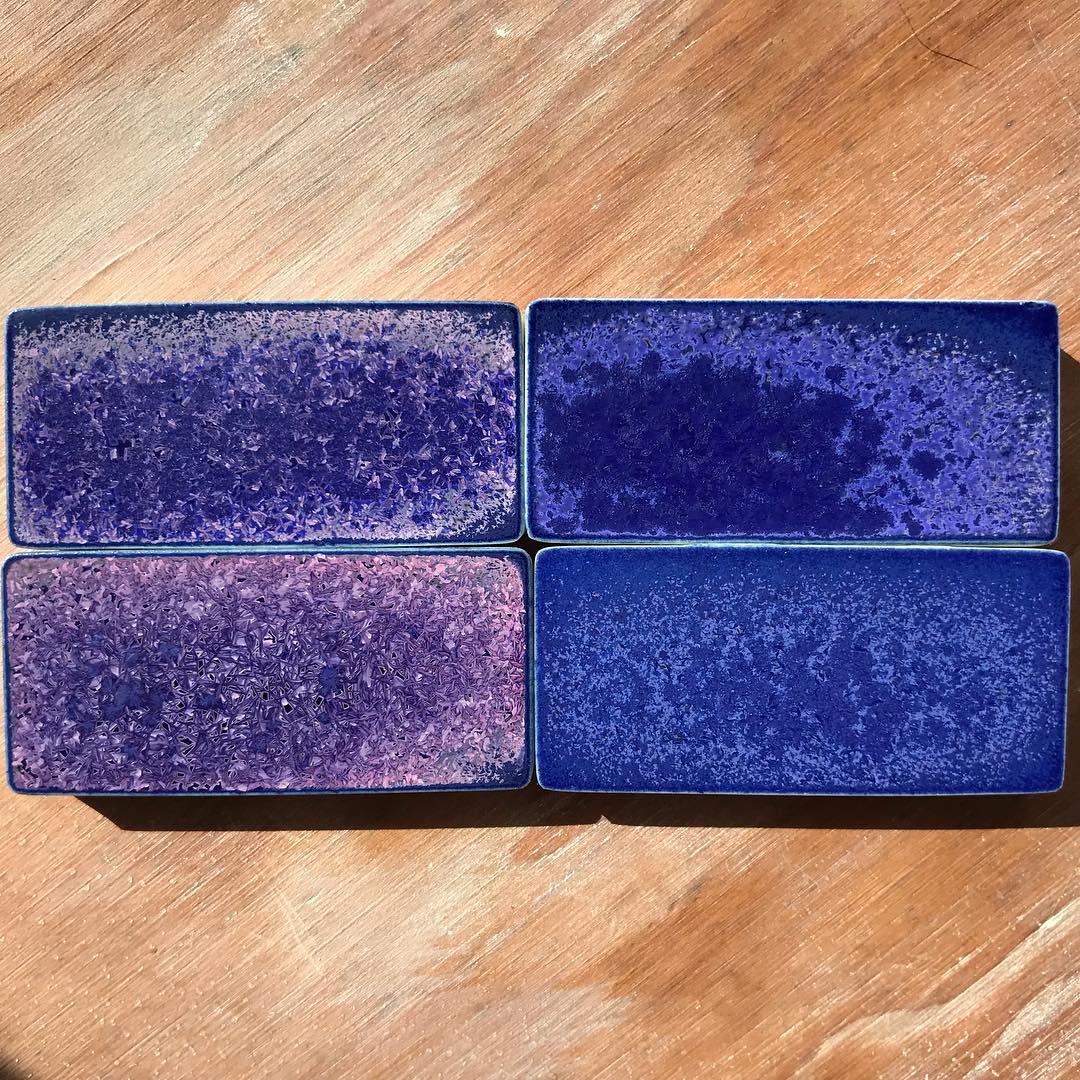

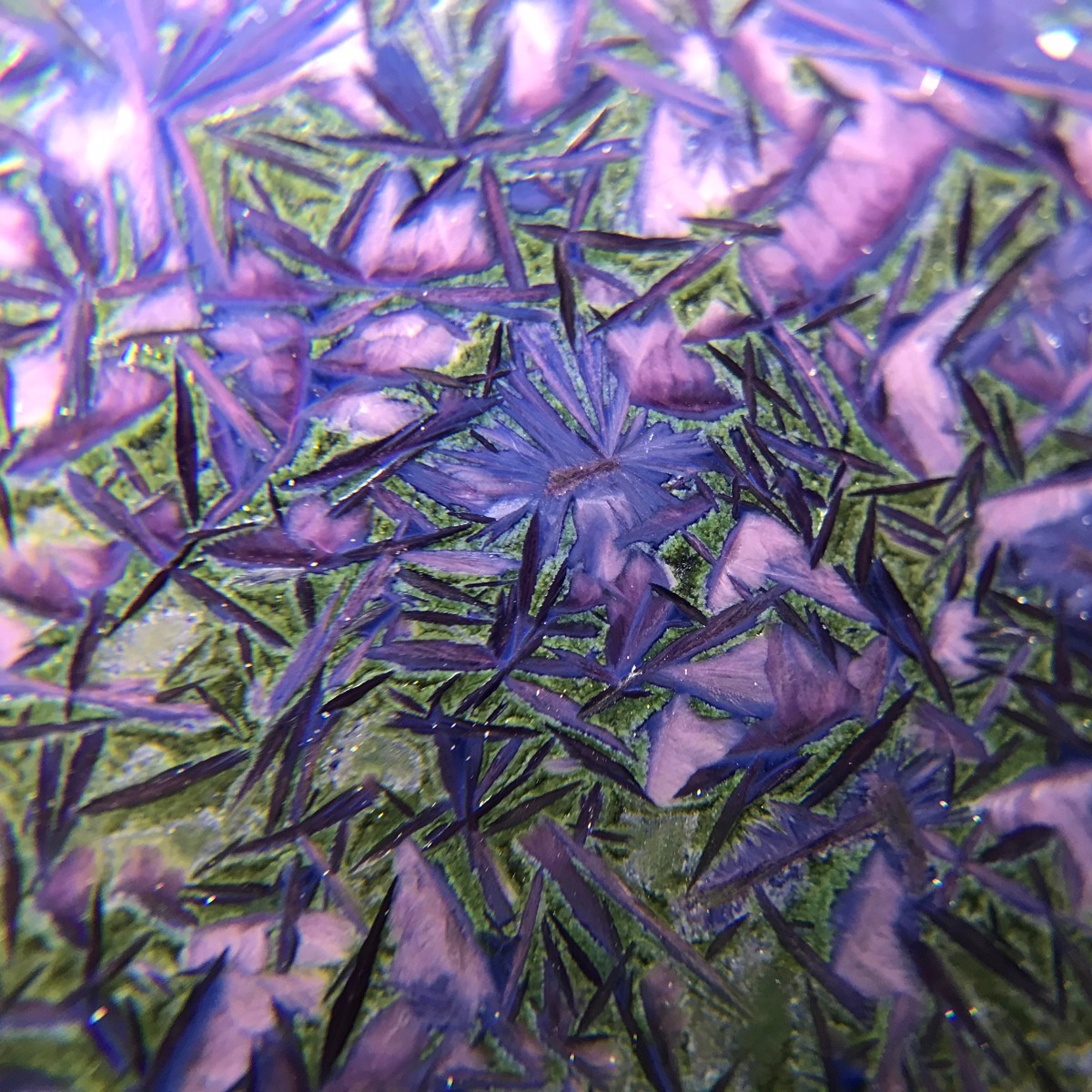

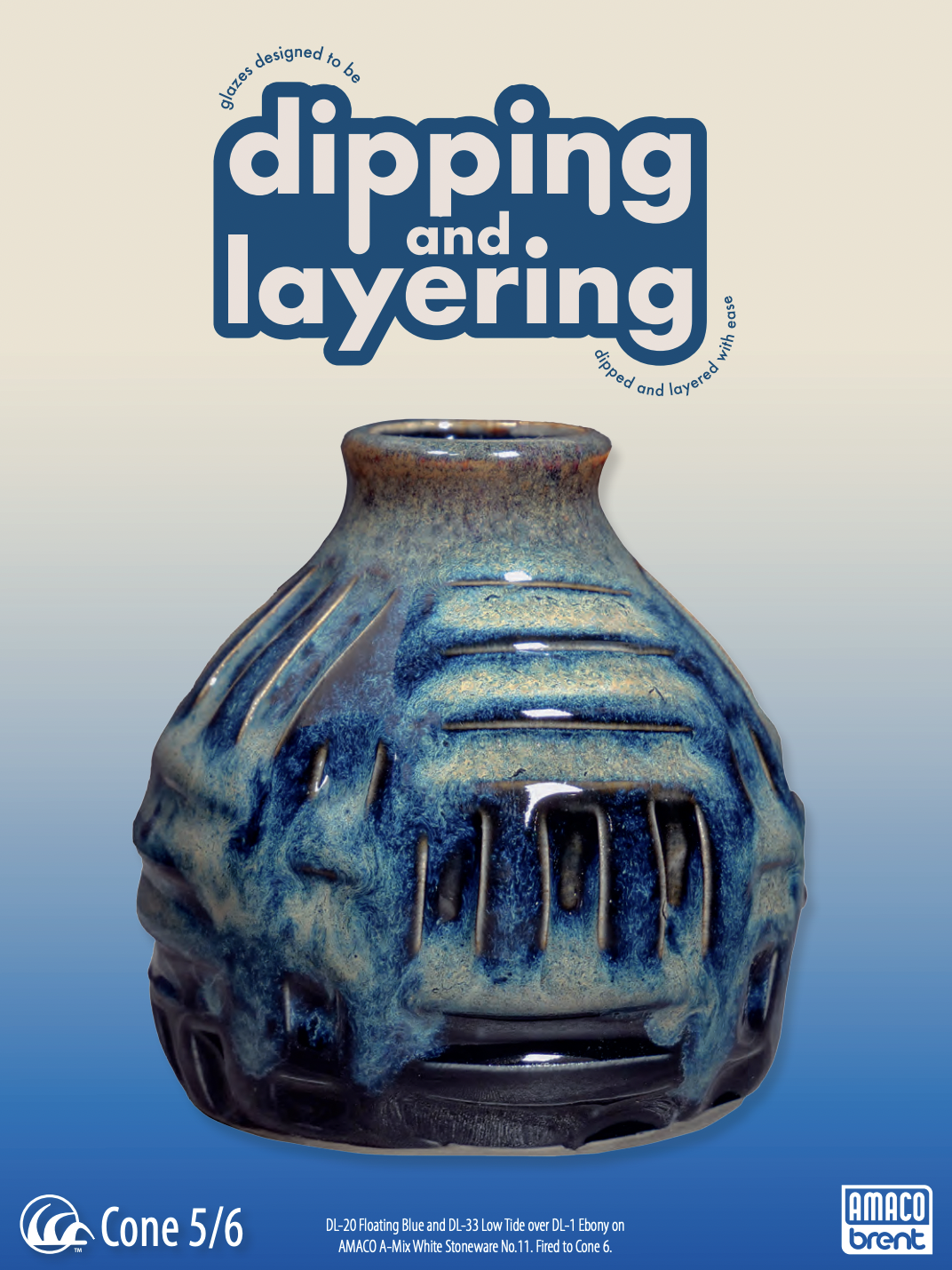

The crystalline glazes I am working on are all developed by Matt Katz of Ceramic Materials Workshop. The glazes are part of his research project that will be at NCECA this year. All I can say is that it’s something new and amazing.

I took my first online glaze class with Matt Katz a year and a half ago, it really changed everything about glaze and ceramics for me. Kicked off a renaissance of sorts for my own ceramic journey and things are just getting started.

I now work together with Matt to help research some cool fun things about glaze chemistry. I apply the things I learn to my own process and continually rebuild upon it.

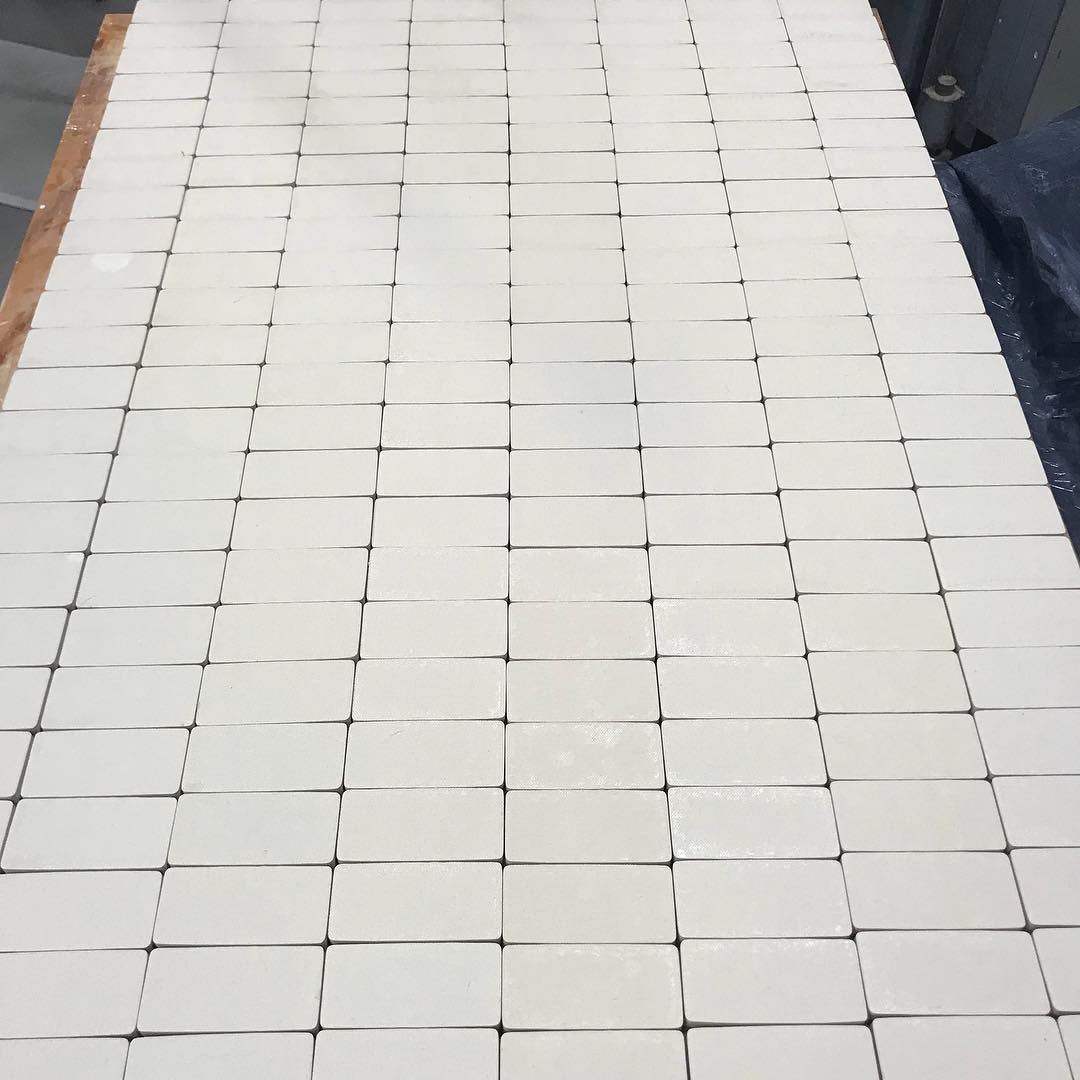

In one of your posts, you show off over a thousand test tiles that you created. Clearly, you have a great system in place for creating uniform tiles. Can you explain a little bit about how that's done?

These specific tiles are used to measure “gram weight” which is the measure of g/in2 of glaze, so they must be as similar as possible in their measurements.

I prep my clay using a Bailey MSV12SS pugmill/mixer, roll out perfect large slabs using myBailey DRD2 slab roller, then I use a custom heavy-duty cookie cutter to make my tiles. The uniformity of tiles is very important to me and it’s the clay prep/slab roll/cut that has the potential to make my tiles warp.

Which Bailey products do you use and how do they help you get the results you need?

I use a Bailey MSV25-SS, my favorite pugmill ever because it is outstanding at preparing clay.

Bailey Pro Wheel, I love everything about this wheel, the enormous splash pan is a dream. Hands down my favorite wheel, it allows me to translate the motion of my hands into the pieces I am wanting to make.

Bailey Thermal Logic, what an outstanding kiln. For the moment I use it to bisque as its too large to fill with test tiles. When I need to glaze large, the TL gives me all the control I need to ensure a quality firing.

A small 3.3 cu ft Bailey TL-1822-10. This is the kiln I use for all my testing. The kiln fires extremely evenly, after calibrating there is only a 3-5 degree F difference between top/mid/bottom. The accuracy and dependability of this kiln is essential to my testing of glazes.

It’s more than just the products, what really helps me is the Bailey customer service. The quality of their products is matched by the quality of their customer service.

Tell us about yourself, how did you get started working in clay?

I live in Hawaii, run a grass farm, and use that to pursue my ceramic adventures. I took my first ceramic class at Punahou with Bob McWilliams as my teacher, went to RISD for ceramics, returned to Hawaii, and eventually built a studio which is where I do all my ceramics today.

What do you love about the ceramic process?

I love how things are all interwoven, taken apart, and rewoven into a new tapestry. It’s how I view the whole crystalline process and ceramics in general.

What are you excited to try next in the studio?

I’m excited about drawing with crystals in crystalline glaze. Yes, you heard correct. I have a long list of things but that’s probably at the top. Overall though, I’m excited about further focusing on glaze research and application.