Tips & Techniques

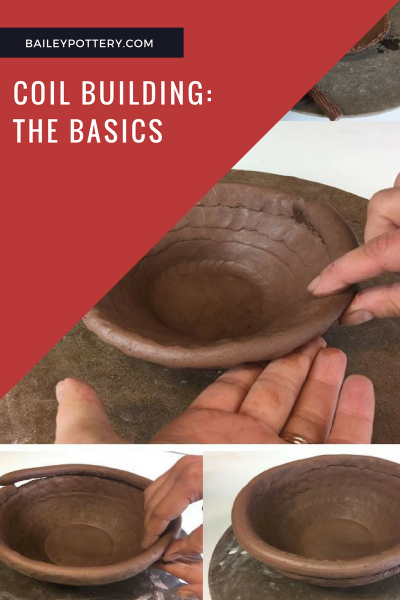

Coil Building Project with Extruded Coils

Form Finding with Coils

With a few swift pulls of the extruder arm, we created dozens of uniform coils perfect for building with. That brings us to this week's post where we are going to show you how to make a bowl using extruded coils.

How to Make Glazes From a Dry Mix

Save on Shipping Costs and Store Dry Mixes for Years

Glazing and Finishing Project, Part 2: Glazing and Finishing with Color and Sparkle!

Lot's of gift giving occasions seem to come up in May. Now is the time to start making some quick and easy coasters for Mom or the newlyweds! If you missed Part 1: Forming Coasters you can see the post here but then be sure to come back because we are about to jump into glazing!

Easy DIY Coasters, Part 1: Make something you can use with this quick project!

We are going to begin by rolling out a slab of clay. We have chosen a low fire white clay with grog from Standard for this project, but you can use any clay you are comfortable with. You can roll out a slab of clay either by using a rolling pin or a slab roller. We used our 22" Mini-Might II Table Roller to roll out this slab.

Who makes the best Jack-o-Lanterns?

Potters! Why?

van Gilder Hump Cut-Off Tool

The One Tool You Just May Need to Add to Your Tool Kit

Water-Slide Ceramic Decals

What they are and how you can apply them to your ceramic work

Brushing Glazes Made Easier

We are going to help you turn those glazes that don't spread evenly and dry way too fast into glazes that you will love to brush with.

Sometimes we have a great glaze that works well when it is dipped, poured or sprayed on but try and brush with it, and that is a whole other issue. Choosing glazes formulated for a brushing application and using glaze additives in glazes that are not already formulated for brushing is the key to making that great glaze behave beautifully when brushed.

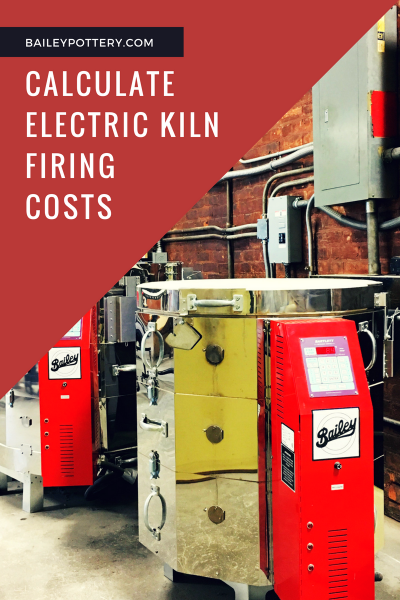

Our Guide to Calculating Kiln Firing Costs

Have you ever wondered how much it costs to fire an electric kiln? Maybe you access a shared kiln and would like to divvy up the cost of a firing. While there are a number of factors that go into overall kiln costs such as studio rent or kiln maintenance, it is possible to hone in on what you pay for a single firing. In fact, we have a guideline that we use to calculate the approximate cost of firing our standard top loading or front loading electric kilns and we are going to share it here with you.

Helpful Hints on Clay Storage

It is best to store your clay in tightly sealed bags to preserve the moisture content of the clay. Ideally, you will want to store your clay in a dark and cool environment. In cold climates, avoid allowing clay to reach freezing temperatures. Remember to monitor your clay, checking on it every now and then to make sure it is not drying out. For general moisture maintenance a spray of water from a spray bottle can assist in retaining hydration.