Glazing and Finishing Project, Part 2: Glazing and Finishing with Color and Sparkle!

Lot's of gift giving occasions seem to come up in May. Now is the time to start making some quick and easy coasters for Mom or the newlyweds! If you missed Part 1: Forming Coasters you can see the post here but then be sure to come back because we are about to jump into glazing!

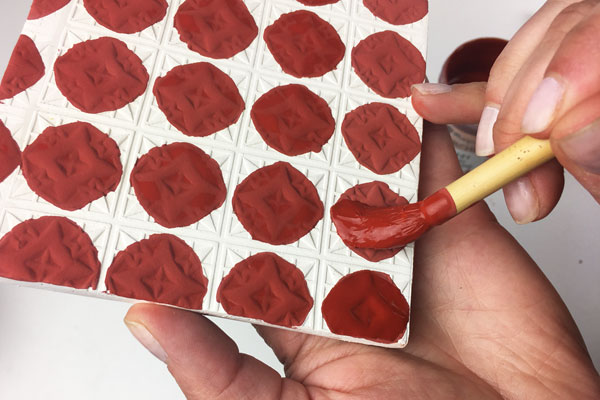

Wipe bisqueware clean with a damp sponge prior to glazing. This should be done every time you glaze to prevent dust from interfering with glaze adhesion. Look at your piece and decide on a plan for glazing. I decided to work into the pre-existing pattern of the form that was created with the textured hand roller in the raw clay.

I brushed Mayco Elements Copper Adventurine glaze onto the bisque ware in thick even strokes. Following the textured lines of the bisque ware, I free-handed a pattern with glaze. Luckily, the fluidity of these glazes is forgiving to imperfections so there is no need to worry about creating perfect shapes. Most commercial glazes require two to three coats of glaze for best results. Because I applied thick applications of glaze, I only needed two coats here.

Next, I brushed two coats of Mayco Elements Lapis Lagoon glaze in the remaining unglazed spaces and overlapped it on select parts of the piece glazed with the Copper Adventurine. The areas where the glazes overlap blend in the kiln firing to create a third amber color.

These pieces were fired in a Paragon 1130 test kiln to Cone 04. To finish the coasters, self adhesive 1/2" Cork Stick-Ons were added to the underside.

Try out these Mayco Elements low-fire glazes for yourself. They are lush with movement and color. The Copper Adventurine has an added sparkle that gives a unique finish to any surface!

April 18, 2017

|

View: 2154

|

Categories: Tips & Techniques

|

Tags: Ceramic Project, Ceramic Tile

|

By: Lyla @ Baileys

Share this post

About the Author

Lyla @ Baileys

Related Posts

Easy DIY Coasters, Part 1: Make something you can use with this quick project!

April 13, 2017| Posted in Tips & Techniques| Lyla @ Baileys| 4112

Extrude Clay Forms with the Bailey Standard Extruder

June 9, 2017| Posted in Featured Products| Lyla @ Baileys| 4746

Create a Bud Vase with Assembled Parts

July 10, 2017| Posted in Tips & Techniques| Lyla @ Baileys| 4423

Fall Leaf Jewelry Dish

October 23, 2017| Posted in Tips & Techniques| Lyla @ Baileys| 19650

Project: Personalize a Valentine, Plus 14 Red and Pink Glaze Picks!

January 22, 2018| Posted in Tips & Techniques| Lyla @ Baileys| 6088

Helpful Hints on Clay Storage

August 4, 2016

DIY Hand-Built Bowl

October 2, 2017

Fall Leaf Jewelry Dish

October 23, 2017

Carve and Glaze Your Way to Spring with Bailey Pottery

March 18, 2024

Let's Mix and Apply AMACO's New Dipping & Layering Glazes!

March 12, 2024

New Video: Assembling the Talisman Sieve

March 1, 2024

Made With a Bailey Interview Featuring Terry Hildebrand

February 19, 2024

Topics

- Customer Service

- Clay

- Bailey Electric Kiln

- Glazes

- Decals

- Throwing on the Wheel

- Ceramic sculpture

- Holiday Project

- Bailey Slab Roller

- Mystery Pot

- The Bailey Collection

- Ceramic Museum

- Kiln Shelves

- Pottery

- Pottery

- Kiln Maintenance

- Ceramic Artist

- Ceramic Tile

- Ceramic Project

- NCECA

- Workshop

- Ceramic Tools

- Atmospheric Firing

- #MadewithaBailey

- Community

- Underglaze

- Gift Guide

- Ceramic Technique

- GR Pottery Forms

- Hydrobat

- Bailey Extruder

Tags

Clay

Mugs

Handmade Pots

Favorite Pots

New Year

Bailey Kiln

Bailey Gas Kiln

Gallery

Pottery Studio

Clay Storage

Bailey Electric Kiln

Ceramic Glazes

Brushing Glazes

Water Slide Ceramic Decals

Pottery Wheel

Pottery Tool

van Gilder Tool

studio visit

Halloween Project

Bailey Slab Roller

Bailey Mini Might II

the Bailey Collection

Mystery Pot

Ceramic Art Museum

Alfred University

Kiln Shelves

Advanced Formula Thermal Lite Kiln Shelves

Bailey Quick Trim II

Penn State University

Kiln Maintenance

ceramic legend

ceramic artist

ceramic sculpture

Ceramic Project

Ceramic Tile

NCECA

Bailey Extruder

Raku Firing

GR Pottery Forms

#MadewithaBailey

Hudson Valley

Gift Guide

Valentine Project

Underglaze Transfers

GR Pottery Forms

Ceramic Technique

Hydrobat

Ceramic Decals

Workshop

Duncan Luster

Holiday Project

Shimpo Handheld Extruder

Extruder

Ceramic Beads

Native American Pottery

My Wish List